-

THE FUTURE TODAY IS SOLID

THE FUTURE TODAY IS SOLID

CLICK ME -

TOP TEN REASONS TO CHOOSE CUBE

TOP TEN REASONS TO CHOOSE CUBE

CLICK ME

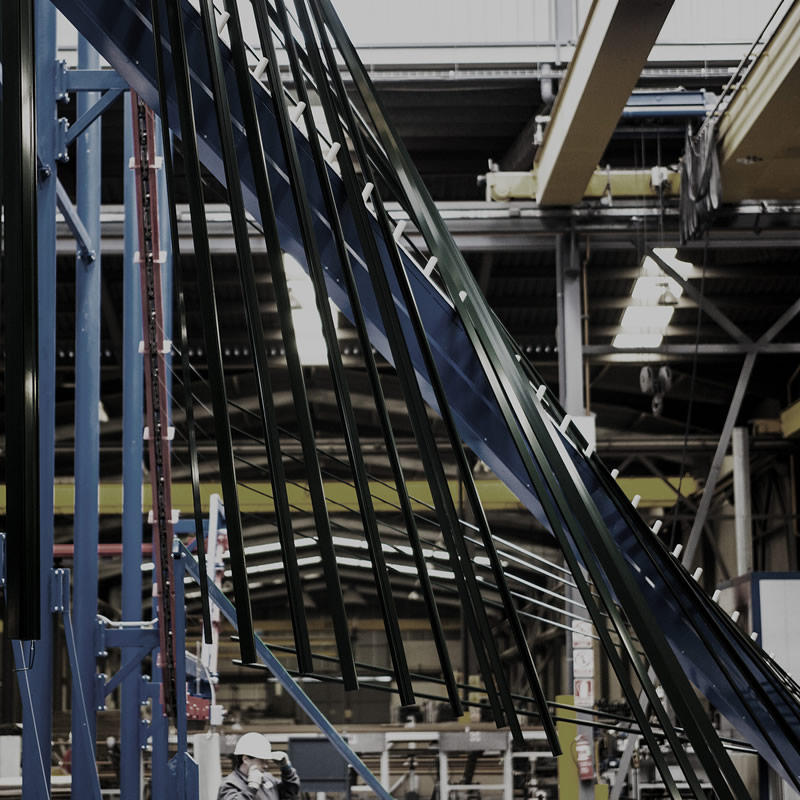

Vertical

The best way to coat aluminium extrusions is to do it in vertical and, since 1981, we are the specialist for this kind of technology.

Compared to the horizontal systems, the main advantages of vertical coating plants are the following:

- Small space required;

- Completely automated process;

- Less workers needed to manage the entire line;

- Fast colour change (5 minutes), that allows a reduction of downtime and a higher flexibility;

- Higher quality of the product thanks to a higher powder transfer efficiency that involves both a higher coat thickness uniformity and a reduction of percentage of powder wasted;

- Higher production: up to 450 profiles/h with the standard CUBE line Vs 100÷150 profiles/h with an average horizontal line;

- Low operating costs and low energy, water and electricity;

- Integrated pre-treatment along the vertical plant.

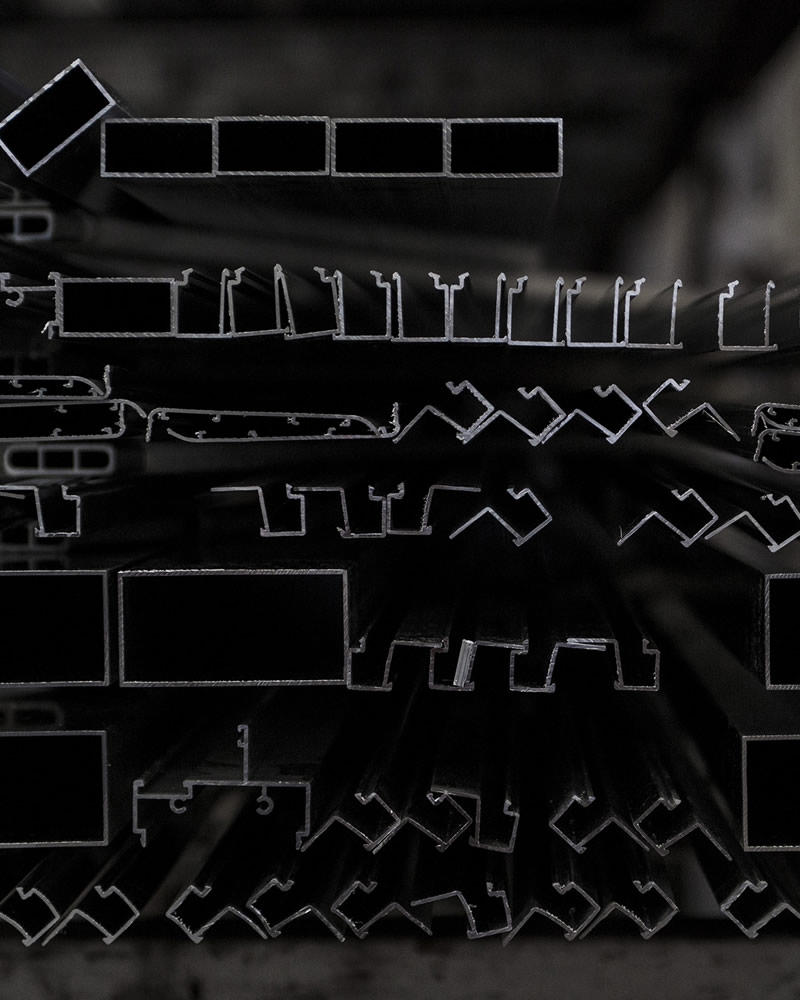

Powder coating

Design

Cube is extremely compact.

The new design of SAT’s painting booth is the result of 2 years of Research & Development by SAT Technical Department: the result is the most selling booth in the industry and 3 European Patents that covers our technology.

The new booth concept dramatically increased the powder transfer-efficiency, that is to say the percentage of the sprayed powder that applies directly on the profiles surface.

In the booth the guns are located on the right and on the left of the profiles and this allows to spray the powder from both sides; the result is a cloud of powder that surrounds the aluminium, with a slower speed of powder and a longer time for powder to stick on the profiles.

Quick colour change

Thanks to the quick colour change system, the booth is cleaned and ready to coat with a new colour in only 5 minutes.

It means to have the possibility to plan the production with high flexibility, fulfilling all the customers’ requests (even the most urgent ones!).

Powder coating

Powder coating

LOWER POWDER CONSUMPTION

The new design has brought to a great reduction of powder consumption due to the following reasons:

• A higher powder transfer efficiency involves a relevant reduction of the overspray and this implies to save powder every time you work without powder recovery, for example for a very short lot or at the beginning of every new colour. Furthermore, the quality of the coating layer is higher because it consists mainly of fresh powder.

• A wider paint brush (the path of the conveyor along which you can spray powder on pieces) allows to perform a higher number of strokes along the profiles. The consequence is that the final layer of powder is the result of the overlapping of a double number of thin layers and this allows to balance the uneven local output of the guns, improving the uniformity of the powder thickness along the profile.

• The new booth allows to get a more balanced coverage between easy and difficult sides of the profiles while keeping a higher chain speed and a higher output race.

As a result, it is possible to get a good thickness on the difficult sides without exceeding with extra thickness on the easy surfaces.

• Thanks to relevant simplification of the powder recovery system, the use of less guns and the cleaning in continuous of the booth, the amount of powder wasted during each color change while cleaning the booth and the powder application equipment is very limited.

STRENGTH IN NUMBERS

The revolutionary impact of the new booth has allowed us to sell 60 units in less than 3 years, including both the new booths and the ones installed to revamp existing installations.

Powder coating

Compact

Cube is extremely compact.

Unlike the traditional powder coating plants (approx. 1000 m2 area required), Cube lines require a small area for its main line components: pre-treatment tunnel, powder booth and ovens.

A more compact line does not mean only saving of space in the building but also:

- Possibility of work-synergy between the plant operators;

- More safety because all equipment remains in the central block of the plant;

- Ergonomic working positions (all “outside” the aerial conveyor);

- Energy saving design (ovens combined);

- Easy and safe maintenance and inspection.

To satisfy all kind of productivity needs, Cube is available in three different versions:

-Cube Standard

With a production of 300 extrusions per hour with a conveyor speed of 0,7 meters per minute.

-Cube Plus

Designed for 600 extrusions per hour with a conveyor speed of 1,4 meters per minute.

-Cube Extra Large

To reach a productivity of 1000 extrusions per hour, with a chain speed up to 3 meters per minute.

Line

Starting from a wide knowledge of the old technology, Cube has launched a meaningful process that has transformed the plant from simple “carpentry” to an intelligent system.

In fact, while the traditional plants were considered mere collections of mechanical components, Cube reverse this trend with the addition of innovative technological contents that have increased the product value and its role in the aluminium finishing process cycle.

THE SOFTWARE SUPERVISION SYSTEM: A CLEAR VIEW ON THE PRODUCTION

In this context, the process control and supervision software play a fundamental role.

The management of the entire process is very simple and allows the repeatability of outstanding coating results.

In fact, the supervision software allows:

1 to follow in real time all orders while running through the plant (also with visualization on the screen)

2 to collect for every order the set of values of all the production parameters

3 to issue for each single order a specific production certificate.

4 to save such parameters in the line database, with the consequence that all data can be recalled anytime

5 to run accurate statistics to follow the production tendency (a very useful tool for plant managers!)

Cube lines in operation

all over the world

Close to you

Trevisan is worldwide leader in the engineering, production and installation of vertical powder coating lines for aluminium extrusions. In 2013 Trevisan introduces in the market the original concept of a vertical compact line.

Via Meucci, 4 - 37135 Verona (ITALY)

T +39 045 8280601

F +39.045.8213937

Info info@sataluminium.com

Sales sales@sataluminium.com

Contact Us

Fields marked with * are required.